Products

Products Center

The Russian 560 pneumatic slips are mainly used for pneumatic mechanized tools for clamping drill pipes, tubing and other pipe strings in the rotary table in oil drilling operations. It is mainly used for бу 2000, бу 2500, бу 3000, бу 4000, бу 5000 and бу 6000 drilling rigs with 560mm through holes. It has the characteristics of convenient installation and disassembly, and can separate the transmission part.

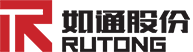

Inclined well drilling rig hydraulic slips

Inclined drilling rig hydraulic slips are mainly used for clamping drill pipe, tubing, casing and other pipe strings in oil and gas drilling operations. The products shall be designed and manufactured according to the requirements of API Spec 7K. All slips can realize hydraulic operation, which effectively reduces the labor intensity of workers and improves work efficiency. The hydraulic slip structure is reasonable, easy to operate, safe and reliable, is an ideal tool for drilling operations. This hydraulic slip can meet the working conditions of vertical drilling 3000m and inclined well 2000m (maximum inclination 45). The inner lining adopts three pieces. By replacing the inner lining, slip body, slip teeth and other parts, the pipe columns with different sizes within the range of 2.7/8 "~ 13.3/8" can be held with a maximum load of 250tons.

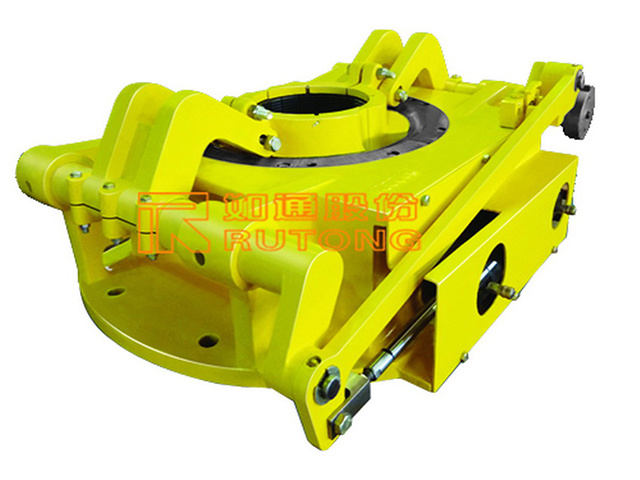

QQP pneumatic chuck is suitable for clamping drill pipes and tubing in oilfield workover operations. The products shall be designed and manufactured according to the requirements of API Spec 7K.

C/CHD/HD pneumatic chuck is mainly used for clamping drill pipe and tubing in oil and gas workover operations. The products shall be designed and manufactured according to API Spec 7K Drilling and Well Servicing Equipment. All chucks can be operated manually, pneumatically or hydraulically, which effectively reduces the labor intensity of workers and improves work efficiency. The pneumatic chuck has reasonable structure, convenient operation, safety and reliability, and is an ideal tool for workover operations.

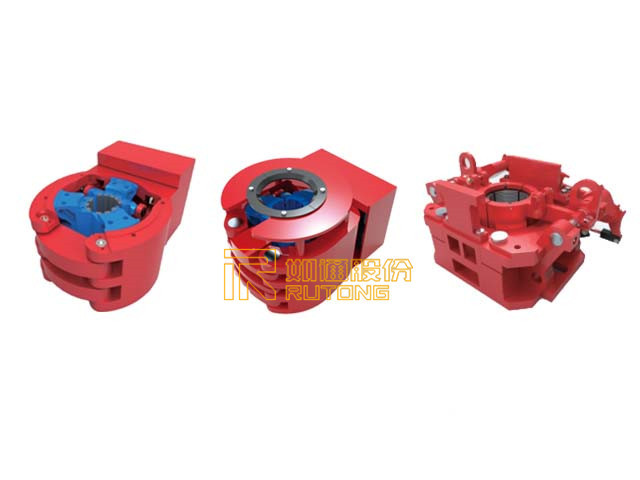

SD series drill pipe slips are suitable for drill pipe diameters of 23/8-7in(60.3-177.8mm). According to the contact length between the slip tooth and the drill pipe, it is divided into short type (SDS), medium type (SDML) and extended type (SDXL). SDS is suitable for shallow wells, SDML is suitable for medium-deep wells, and SDXL is suitable for deep wells. The products shall be designed and manufactured according to the requirements of API Spec 7K.

DU series turnplate slips are composed of DU type, DUL type and SDU type. The slips have a wide fastening range and light weight. Among them, SDU type slips have large back cone contact surface and high strength. The products are designed and manufactured according to API SPEC 7K requirements.

B type drill pipe slips consist of B Short type, B Long type and X Long type. The products shall be designed and manufactured according to the requirements of API Spec 7K. The unique torque transmission tooth groove design makes all torque directly transmitted to the slip body, preventing the tooth plate groove from wearing and improving the service life of the slip.

DCS drill collar slips are available in S, R and L models, which are suitable for clamping drill collars with diameters of 3in (76.2mm) to 14in(355.6mm). The clamping size can be changed by replacing dental plates or increasing or decreasing the number of slips. Products are designed and manufactured according to API SPEC 7K requirements.

The A- type drill collar slips are of multi-piece structure, which can adapt to the change of the outer diameter of the drill collar after wear, and have the advantages of light weight, large clamping range and firmness. The product shall be designed and manufactured according to the requirements of API Spec 7K.

CMS-XL the sleeve slip is matched with the matching lining or bushing, the diameter of the sleeve that can be held is 41/2- 30 in(114.3-762mm). The products shall be designed and manufactured according to the requirements of API Spec 7K.

The UC-3 type casing slip has a 1:4 slip back cone (except 85/8 slips), which is a multi-piece design for clamping the casing. Each slip body of a set of slips has the same acting force, the force is uniform, and the pipe string is not easy to deform. The slip shall be used together with the chuck and lining with a taper of 1:4. The product shall be designed and manufactured according to API Spec 7K.

Sales:86-0513-84510292 84129120

Foreign trade sales: 86-0513-84129149 84511086

Fax: 86-0513-84523102

Mail:rdty@rutong.com

Address: 33 Huaihe Road, Rudong County, Nantong City, Jiangsu Province

©2024Jiangsu Rutong Petro-Machinery Co., Ltd. ALL Rights Reserve.